Add to Cart

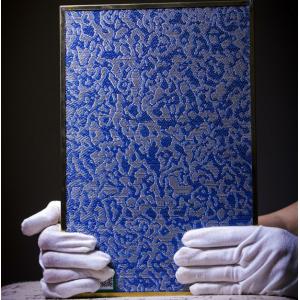

Typical metal mesh textile sandwich glass is 2.5mm glass, 0.38mm laminated glass, and 2.5mm glass. Obtain the final product, called 5.38 laminated glass.

| interlayer materials | stainless steel, copper, brass, aluminum alloy wire mesh, etc. |

| glass type |

|

| Whole thickness of sandwich glass |

|

| Whole size of sandwich glass |

|

metal mesh textile sandwich glass is a type of safety glass that binds together when broken. In the event of fracture, it will be fixed through an intermediate layer (TPU) typically consisting of polyvinyl butyral (PVB), ethylene vinyl acetate (EVA), or thermoplastic polyurethane, located between two or more layers of glass. The middle layer can maintain the bonding of the glass layer even if it breaks, and its high strength can prevent the glass from breaking into large sharp fragments. When the impact force is not sufficient to completely penetrate the glass, this will produce a characteristic "spider web" cracking pattern. In the case of EVA, thermosetting EVA provides complete bonding (cross-linking) with glass, polycarbonate, PET, or other types of products. TPU is the best choice for bulletproof glass (BRG) and so-called smart glass.

metal mesh textile sandwich glass is usually used in areas where glass that may be injured or broken may fall, and can also be used in building applications. Sunroof glass and car windshields usually use laminated glass. In geographical areas where hurricane resistant buildings are required, metal mesh textile sandwich glass is typically used for exterior storefronts, curtain walls, and windows

The plastic interlayer in snadwich glass makes it difficult to cut. The unsafe approach is to cut both sides separately, pour volatile liquids (such as denatured alcohol) into the cracks, and then ignite them to melt the intermediate layer to separate the fragments. The UK government's Health and Safety Executive proposed the following safer methods in 2005: